800-335-6718

Custom solutions for all your Continental Motor needs

Open Product

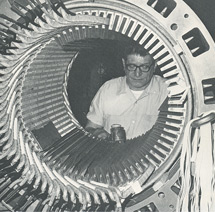

Continental Electric Motors offers a broad selection of high-horsepower, drip proof, splash proof, weather protected horizontal and vertical motors. While most applications call for constant speed, Continental's selection includes variable speed motors such as wound rotor and VFD capable variable speed motors. Sturdy construction and precision balancing minimize vibration across the entire speed range. The result is quieter operation, less wear, and longer lasting performance. This remarkably smooth, quiet operation has made Continental the choice of prestigious sites, including The United Nations, Newark and Tampa airports, The White House, and others.

A choice of optional accessories provides the capability to adapt Continental's vertical motors to a broad range of applications. These accessories include heavy-duty explosion proof oil-lubricated (liquid or mist) bearing cartridge assemblies, audio noise dampening kits, space heater, vibration detectors, and thermal detectors for windings and bearings, or other safety or motor monitoring systems as specified.

Drip Proof

Open construction and ventilation ports allow cooling air to circulate freely around the windings. The ports are designed to prevent liquid drops or airborne solid particles from entering the housing when introduced at angles from 0° to 15° from vertical.

Splash Proof

Open construction and ventilation ports allow cooling air to circulate freely around the windings. The ports are designed to prevent liquid drops or airborne solid particles from entering the housing when introduced at any angle greater than 60 degrees downward from vertical. The motor is protected against solid objects greater than 1.968 inches, (50 mm).

Drip Proof Guarded

Guarded motor construction includes structural components including but not limited to screens, baffles, grills, expanded metal, or other means that prevents accidental contact with hazardous parts the likes of live metal or rotating parts. Semi-Guarded motors provide guarded motor construction, as described above, but limited usually to the top half of the motor. In Continental horizontal motors, the minimum motor enclosure provided is Drip Proof Guarded. In Continental vertical motors, the minimum motor enclosure provided is Weather Protected Type I.

Weather Protected Type I

Weather Protected Type I motors are identical to drip proof motors. In addition, a 3/4" mesh screen completely covers the ventilators. This protects the motor by preventing the entry of rodents and reptiles, twigs, leaves and other potentially harmful material, while also minimizing the entry of snow and rain. All parts of the motor, both external and internal, are treated with corrosion inhibitors, and insulated with moisture-resistant CECO-Seal.

Weather Protected Type II

Improved ventilation, insulation and sealing systems allow Weather-Protected II motors to be used in areas previously reserved for totally enclosed, fan cooled motors. Ambient air, drawn into the motor by a circumferentially-screened frame opening, is directed upward at velocities of 600 ft/min or lower. When specified, the air is filtered to remove any particulates.

A portion of the air passes the shaft and cools the thrust bearing, then turns downward to cool the top half of the motor. The remaining air is directed to the bottom of the assembly, and is used to cool the motor's lower half. Heated air exits through baffled openings in the lower frame.

Both air passages - for the upper portions of the motor and for the lower - contain at least three abrupt changes in direction. This reduces the possibility of dirt or moisture from entering the fans and windings. Storm winds pass through the external air passages, and are prevented from entering the motor's active area. WPI is standard for Continental Vertical Ratings. WP I & II is additional for Continental Horizontal Ratings. WPII is additional for Continental Vertical Ratings.

sales@cecoinc.com

sales@cecoinc.com